Expertise

Product co-design

Our long experience in the study, development and manufacturing of innovative product geometries allows us to offer customers the product design that best responds to the specific functions and conditions of use of the part, and any existing manufacturability and cost constraints.

Our philosophy is to involve the customer from the earliest stages of designing the geometries of a new product, acting as a direct contact between our R&D department and the customer's technical area and providing our team of highly specialised engineers.

Our involvement in the co-design allows our customers to increase the effectiveness of our solutions and at the same time to decrease the time-to-market, minimising manufacturability issues and ensuring due attention to cost optimisation.

Activities

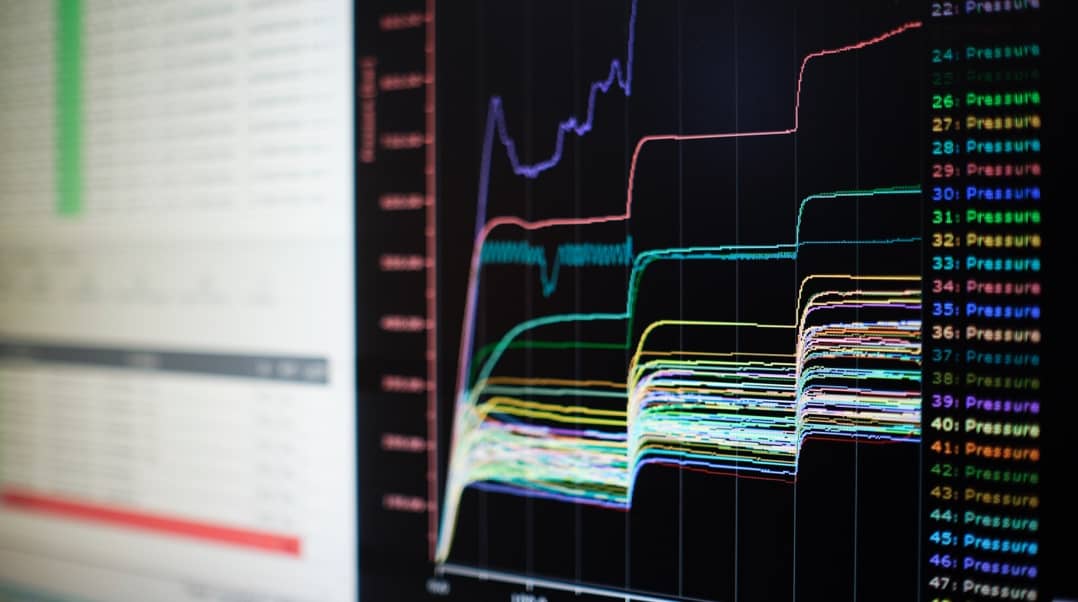

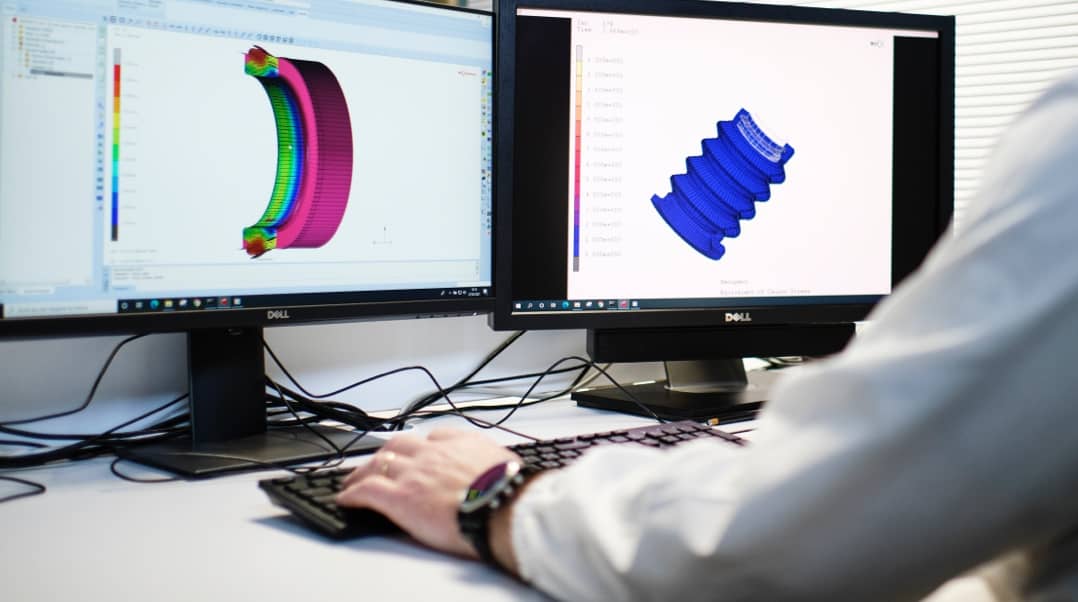

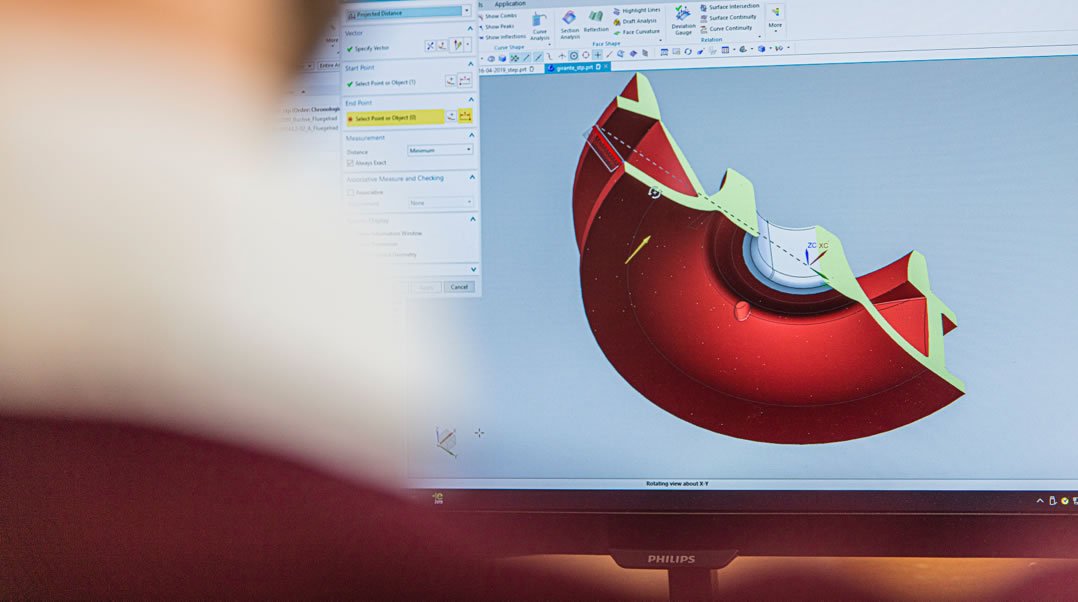

- Identification of the geometry best suited to the customer's functional requirements thanks to simulation and structural calculation software that supports the study and development of the product design.

- Exchange of project inputs and outputs via EDI systems, guaranteeing the necessary confidentiality and security in the exchange of data.

- Ability to work in different 2D and 3D CAD formats.

- Availability of cutting-edge design software to support and validate the proposed product geometry; in particular, the Moldflow software that allows simulations to be carried out and provides detailed indications on any critical issues associated with the injection moulding process of the part being studied.

- Availability of a FEM calculation system, specific for polymer problems, to support and validate the proposed solutions

- Significant experience in metal-replacement projects with numerous important projects developed on parts previously made of metal and now made of technopolymers